At Mustard, we care deeply about the way we do business and the impact we have on our environment. This year we set ourselves the challenge of sharing our sustainability wins with our customers. Putting the things we care about into practice doesn't always happen overnight — it's about the small, incremental changes that make a big long-term difference. We love the quote 'done is better than perfect', so in that spirit, here's some of the projects we've been working on.

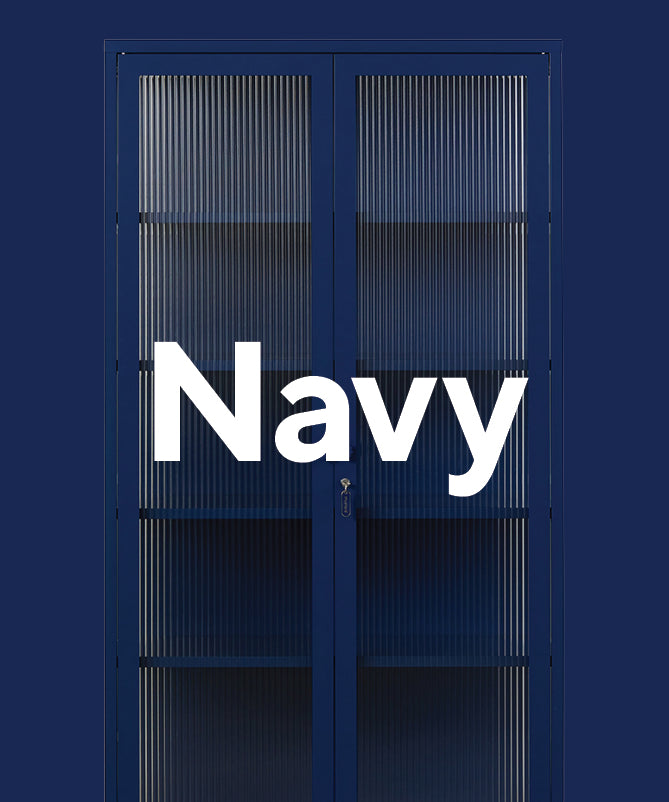

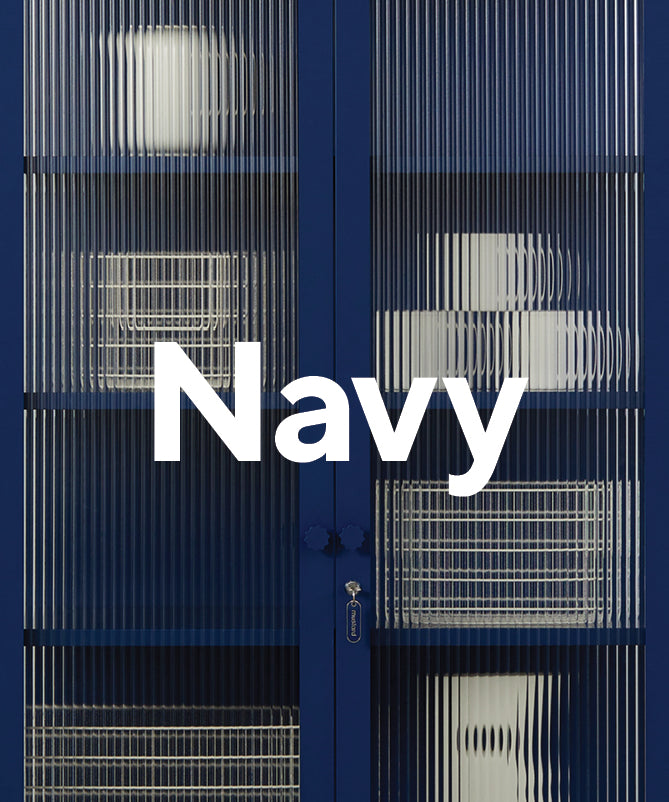

Mustard started because Becca rescued an old, rusty locker that had been dumped on the side of the road. It had definitely seen better days, but Becca saw something in it, took it home and gave it a second chance at life. Inspired by a very unloved old locker, Becca knew that Mustard's lockers needed to be something people would love so much that they'd want to keep them forever.

Our products go against the throw-away consumer culture, they are made to last and be timeless. The most sustainable piece of furniture is the one you keep for a lifetime.

With a global business that continues to grow, we're acutely aware of our potential impact on the environment. Looking at the big picture is just as important to us as all the small changes we can make. This year, we're working on ticking off our to-do list of changes, and we're happy to share an insight into the progress we've made so far.

in it for the long haul

A big factor in our approach to sustainability goes back to our goal of creating timeless products that are designed to last. We want our lockers to be with you throughout many seasons of your life and to always have a purpose. We don't chase trends and we think very carefully about adding new products to our range. This ethos impacts the way we design our products and also, how we sell them. We want our customers to make considered purchases and to invest in pieces they'll want to keep long term.

Our hope is that our lockers will be reused, repurposed and enjoyed by different generations (and will never end up being dumped on the side of the road!)

parts not products

One area we have really invested in is spare parts. Now, we really do wish we could find a way to ensure every product arrives perfectly intact, but despite our very best efforts, we know that damages can happen. So, when things do go wrong, what do we do?

The simplest option would be to send a new product. This is not only costly but also means that the customer is left with a locker they probably don't want or a bunch of parts that they can't do much with! We don't love asking our customers to ship them back because repacking flat packs is a bit like trying to put a genie back in a lamp! It's definitely possible (we'll guide you through it if you ever need to!) but it's not the most fun and often leaves the pieces susceptible to even more damage. In our factory, every locker is packed by 6-8 experienced packers — it's impressive!

Our solution is to keep a library of the most important spare parts. This means we are able to send out only what is needed, keep waste down and quickly solve issues. Plus, any damaged parts can be recycled as steel is one of the most endlessly recyclable materials!

It takes a lot of time and effort to manage all our spare parts, especially as our range has expanded, but it makes us really proud to offer this as a practical solution.

move over polystyrene

Our products are big and bulky, so protecting them during transit is seriously important. In the early days, our aim was to have as little packaging as possible. We quickly learnt that the couriers weren't always as gentle as we hoped they'd be with our precious locker babies! We worked incredibly hard to find the best solutions which ultimately meant adding more packaging.

We've been working to transition our soft padding from polystyrene to EPE, which is a type of recyclable foam that actually absorbs more impact too. Now, nearly all our products are packed with EPE.

We also developed what we like to call our 'honeycomb jacket', which we use to safely wrap the parts and provide all round protection. It's like a big hug for the parts and it's completely recyclable!

getting krafty

When packaged, our keys are attached to the locker door so the lock and key pair stay together. We'd been using plastic cable ties but wanted to find a better option that wasn't plastic. It needed to be simple and sustainable plus keep the keys safe! In comes our little kraft stock bag ties!

Since making this change at the end of 2024, we have saved 21 kg of plastic cable ties! This is equivalent to about 1050 small plastic bottles.

We estimate that throughout 2025, we will save 68 kg of plastic. It's a small change with huge results!

swatch solutions

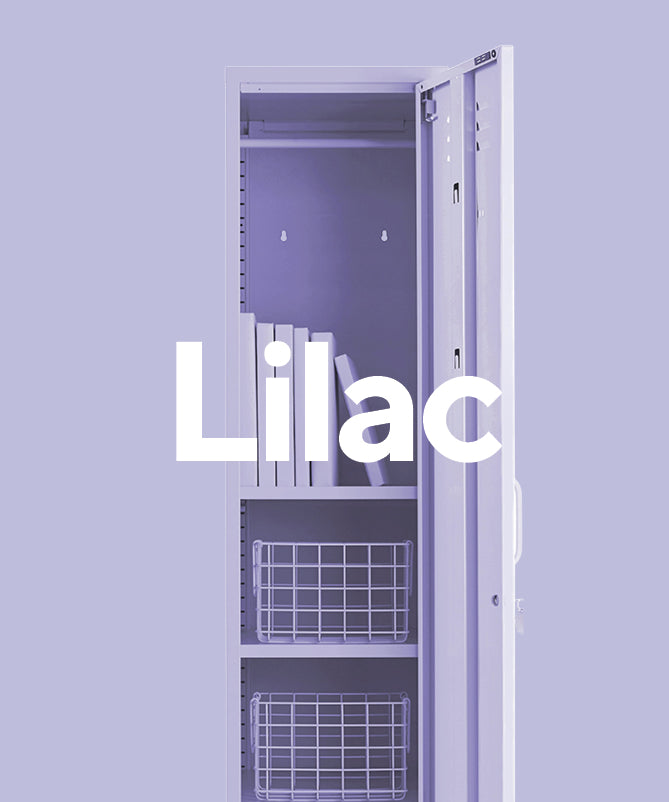

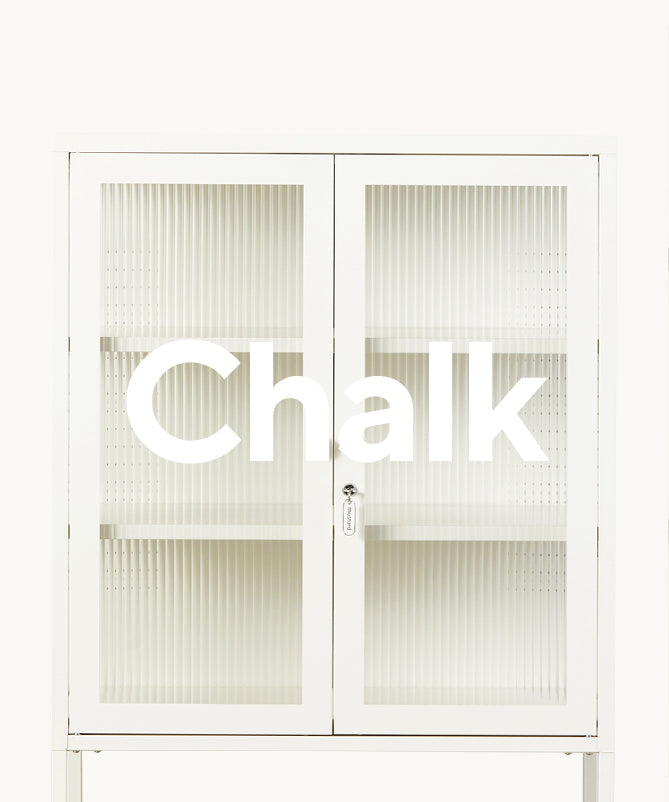

We offer swatches first and foremost because we want our customers to love what they buy. Managing returns is a huge waste of resources: with flat-packed furniture, it's unlikely we'll be able to sell a product that has been opened, so we want our customers to make the right choice first time. Enter Colour Swatches! They help reduce the decision overwhelm and because they are made of steel, they are recyclable (check with your local council for recycling options). We also encourage you to think of ways to reuse your swatches once you've picked a colour. We've got a few ideas on our blog, or send them back to us and we'll reuse them!

One current project is to simplify our swatch packaging. The old packaging: tissue paper, sticker, postcard, padded envelope. The new packaging: custom-designed, FSC kraft stock, all-in-one fancy box. The best bit is that you can rip off the outer layer (with the shipping label on) and it becomes a lovely box that you can keep if you want to. Don't need it? It's totally recyclable. We're so close to getting these finished and we can't wait to share them with you soon!

small parts, big wins

Small things matter, including all the little things you need to build your Mustard pieces. When we launched, we worked with our factory to make some simple improvements to the way our small parts arrived. We put them in a simple box that was low cost and fully recyclable – that felt good. What didn't feel so good was the small plastic bags that the pieces went in to stop the screws scratching the handles or the brackets scratching the medallion keyrings. We also didn't want all the little parts to arrive in a mess!

We've been chipping away at the problem for a long time and finally have an answer we love! An extremely clever kraft box that has spots for everything to be kept safe and sound. We're rolling this out across our range this year and it feels so good to know we don't have to compromise on protection or rely on plastic bags any more!

roll out the (plastic-free) tape

Another goal we're working towards is transitioning our packing tape to a plastic-free one. We were all ready to roll it out but hit a roadblock when we discovered that the tape had started peeling off in the humidity at our factory. Yikes! We really can't have our boxes unboxing themselves on their journey! Like many things, it's been a process of trial and error as we work towards finding a solution that will be plastic-free but still hold all the important bits together long term. So, we're back to the drawing board, working with our suppliers to find a tape and a suitable application process for our lockers that ticks the boxes. This process has reminded us that changes don't just happen overnight, but are worth sticking with!

The good news is that we started using plastic-free tape on our Baskets this year and upgraded the protective wrapping inside from poly bags to honeycomb kraft paper. This means The Baskets are our first totally plastic-free products!

The theme for Earth Day this year is 'Our Power, Our Planet' and a reminder that we all hold the power to make positive changes, even if it's as small as cutting ties with cable ties.

We're prioritising progress over perfection and we can't wait to share more as we continue to work towards our sustainability goals!

Leave a comment